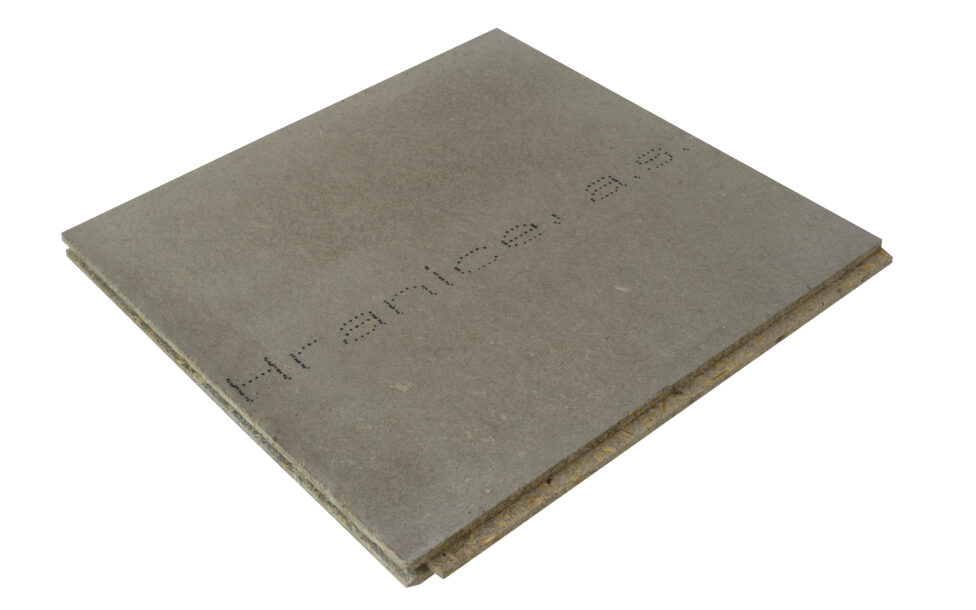

Cetris PD

CETRIS PD tongue-and-groove cement-bonded particleboard has a smooth surface, and it is produced by pressing a mixture of wood chips(63% vol.), Portland cement (25% by volume), water (10% vol.), and moisturizing ingredients (2% vol.), followed by cutting and milling.

Cetris boards combine favorable features of cement and wood. They are lighter than conventional cement-fibre boards, their strength and resistance against weather conditions, frost and mould ranks them higher than cement bonded chipboards or gypsum plasterboards.

They are fireproof and can provide sound insulation. The boards can be worked with conventional woodworking tools.

Product sizes

Standard sizes: 1,250 x 3,350 mm; 1 250 x 2 600 mm; 1 250 x 745 mm.

Standard thickness: 16 mm. Other sizes and thickness are available on request.

If necessary, the boards can be cut to a suitable format after your specification and pre-drilled for fixing with screws.

We deliver the boards cut to the sizes specified by the customer, with rounded edge or chamfered edge to 45° angle, milled starting from the 12-mm thickness with half-groove, starting from the 16-mm thickness with tongue and groove.

CNC service available upon request.

Properties

- Fire resistant - their classification according to flame reaction pursuant to the European standard EN 13 501-1 is A2-s1, d0–non-flammable.

- Environment friendly, ecological. They contain no hazardous substances such as asbestos and formaldehyde and they are resistant to petrol and oils.

- Frost-resistant- tested successfully by 100 freezing-defrosting cycles pursuant to ČSN EN 1328 standard.

- Weather resistant - the best material for wet rooms and weather-exposed exteriors for its excellent humidity resistance.

- Hygienic, odorless and contain no hazardous substances.

- Perfect sound barrier- provide for acoustic insulation (sound transmission loss 30 – 35 dB).

- Fungi and mould resistant - mould does not form on the board surface thanks to the board’s resistance to humidity.

- Absolutely insect resistant thanks to their cement content.

Application

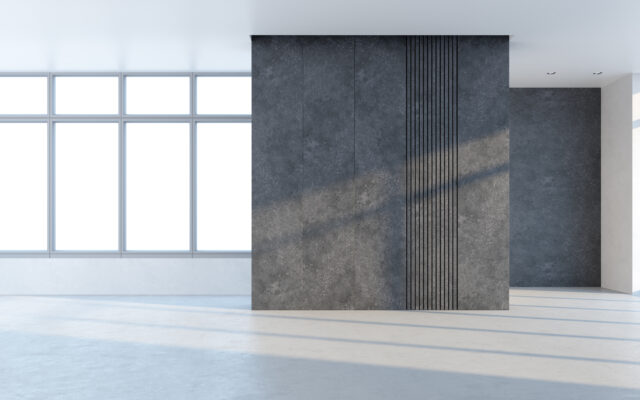

CETRIS boards are a building material with excellent properties, mainly as a structural material:

- floor systems, walls, ceilings and plinths;

- roofs, attic adaptations, attic superstructures;

- fire protection;

- disposable formwork systems, elevator shafts;

Also perfect for:

- ventilated facades, balconies;

- in cases where moisture resistance, strength, fire resistance, ecological and hygienic harmlessness are required at the same time.

Installation

Can be processed by all commonly available wood processing machines. The professional treatment of boards requires tungsten carbide tipped tools. The boards may be cut, drilled, milled and grinded. The boards may be attached to structures by screwing, or riveting. Alternatively, Cetris board may be attached to a load-bearing structure by gluing or with clamps. Both methods are used, in particular, to attach boards in suspended vented facades.

The boards may also be delivered with pre-drilled holes.

Transportation & storage

During transportation and storage, the plates must be protected from moisture, dirt, dents, and scratches. When covering the boards with a water-repellent material (e.g. film), ensure sufficient ventilation of the boards.

Cetris boards are placed on wooden transport pallets for forklift handling. The boards are fixed to the platform using a banding in a crosswise manner; longitudinal banding is possible upon the customer's request.

The boards are protected against weather conditions with a PE foil packaging. This packaging type does not meet conditions for long-term weather exposure by open-air storage.

Cetris boards should be stored in roofed, dry space to prevent moisture absorption by the boards before installation in the building structure.

When storing boards without surface finish pallets of the same size can be stacked. Pallets with boards with surface finish cannot be stacked.

Cetris boards should be placed on a pallet for handling. If stored differently the boards should be handled vertically. Also, manual transport should be carried out with the boards in vertical position.

Documentation

Technical data

| Table of basic physical and mechanical properties of CETRIS® cement-bonded particleboards: | Limit values according to standard | Mean values - real |

| Bulk density acc. to EN 323: | min. 1,000 kg/m3 | 1,350 kg/m3 |

| Bending tensile strength acc. to EN 310 | min. 9.0 N/mm2 | min. 11.5 N/mm2 |

| Modulus of elasticity acc. to EN 310 | min. 4,500 N/mm2 | min. 6,800 N/mm2 |

| Tensile strength perpendicular to the board plane acc. to EN 319 | min. 0.5 N/mm2 | min. 0.63 N/mm2 |

| Internal bond after cycling in a humid environment according to EN 321 | min. 0.3 N/mm2 | min. 0.41 N/mm2 |

| Reaction to fire acc. to EN 13 501-1 | A2-s1, d0 | |

| Index of flame propagation along the surface acc. to the Czech standard ČSN 73 0863 | i = 0 mm/min | |

| Thickness swelling when stored in water for 24 hours | max. 1.5 % | max. 0.28 % |

| Thickness swelling after cycling in a humid environment according to EN 321 | max. 1.5 % | max. 0.31 % |

| Linear expansion with changes in humidity from 35% to 85% at 23 °C according to EN 13 009 | max. 0.122 % | |

| Water absorption by the board when stored in water for 24 hours | max. 16 % | |

| Thermal expansion coefficient acc. to EN 13 471 | 10 × 10-6 K-1 | |

| Coefficient of thermal conductivity acc. EN 12 664; thickness 8 to 40 mm | 0.200 - 0.287W/mK | |

| Airborne sound insulation according to Czech standard CSN 73 0513, th.8 to 40mm | 30 dB – 35 dB | |

| Diffusion resistance factor according to DIN EN ISO 12572, th.8 to 40 | 52.8 – 69.2 | |

| Resistance to frost at 100 cycles according to EN 1328 | RL > 0.7 | RL = 0.97 |

| pH of the board material | 12,5 | |

| Mass activity Ra 226 | 150 Bq/kg | 22 Bq/kg |

| Mass activity index | I = 0.5 | I = 0.21 |

|

Surface resistance to water and chemical de-icing agents acc. to Czech standard CSN 73 1326 |

Waste after 100 cycles max.

800 g/m2 (Method A) |

Waste after 100 cycles max.

20.4 g/m2 (Method A) |

| Waste after 75 cycles max.

800 g/m2 (Method C) |

Waste after 100 cycles max.

47.8 g/m2 (Method C) |

|

| Resistance to arc discharge of high voltage according to EN 61 621 | th. 10mm, min.143 sec | |

| Shearing friction coefficient acc. to the Czech standard ČSN 74 4507 | Static μs = 0.73 | |

| dynamic μd = 0.76 | ||

| Mass balanced humidity at 20° and a relative humidity of 50% according to EN 634-1 | 9 ±3 % | 9.50% |