SILBONIT Hydro/HydroPlus Standard

SILBONIT are asbestos free double pressed and autoclaved flat boards. They are reinforced with mineralized cellulose fibres and through coloured, with smoothed surface and rectified edges. Silbonit boards are CE marked according to EN 12467. Their excellent mechanical properties make them one of the most suitable finishing materials for reliable and elegant, high-quality solutions.

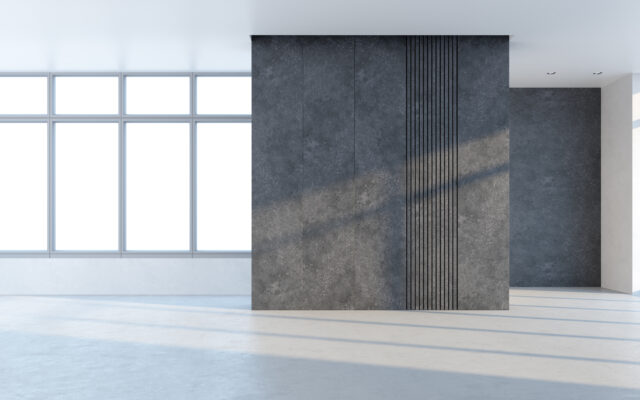

Silbonit cladding boards are specially designed for external cladding, semi exposed and external lining applications. Applied on a ventilated façade, Silbonit fiber cement products are strong, durable and lightweight, which provides an attractive cost-effective solution for a wide variety of projects. Can also be used for internal design solutions.

Through coloured range is available in Hydro or HydroPlus treatments.

Product colors

13 different through coloured shades and a smoothed surface give Silbonit Hydro and Hydroplus finishing boards an extremely natural appearance, which is their main feature.

Non uniform colours and some small imperfections of the surface are a feature of the product.

Colours, even through reproduced with great care, can vary compared to the original ones. For colour choice, one must decide from samples, keeping in mind that some difference in tone is possible between different batches and that every board is unique.

090 Blu

090 Blu

050 Verde

050 Verde

040 Giallo

040 Giallo

061 Terracotta

061 Terracotta

060 Rosso

060 Rosso

031 Lavagna

031 Lavagna

030 Grigio

030 Grigio

011 Pietra

011 Pietra

080 Deserto

080 Deserto

010 Bianco

010 Bianco

070 Terra

070 Terra

081 Pergamena

081 Pergamena

020 Naturale

020 Naturale

Product sizes

Standard Size: 2500x1200 mm; 2500x1250 mm; 3000x1200 mm

Thicknesses: 6 mm; 8mm; 10 mm; 12 mm

Properties

- Excellent mechanical resistance.

- Non-combustible material CAN/ULC S114 tested, class A2 s1 d0.

- Easy to fabricate and install.

- Resistant to rot, fungus & vermin attack.

Application

Silbonit boards can be used for various purposes, but their basic application is in ventilated facades and interior decoration.

External cladding, semi-exposed & external lining applications.

Installation

Silbonit façade boards must be installed on vertical timber battens or vertical metallic profiles, with a maximum spacing of 60 cm between fixings. 8 mm thick boards are admitted for installation with visible mechanical fixing. For concealed fixing, thicker boards must be used.

An adhesive gasket must be placed between the sheets and the vertical profiles of the subframe, which must not be longer than 3 meters. The number of fixings per square meter is according to the size of the sheets, the distance of the subframe from the wall and the conditions of use. The fixings must be aligned both vertically and horizontally. The boards should be pre-drilled. The corner holes must not be equidistant from the longitudinal and transverse edge. No percussion tools should be used to drill the holes. The diameter of the hole should be larger than the diameter of the screw or rivet (except for the fixed point). Countersunk screws should not be used. A gap of at least 8 mm is necessary between the sheets, both lengthwise and widthwise. Use circular saws with diamond blades to cut on site; the cut is to be made dry.

Warning. The above information is purely indicative, although it is based on our many years of experience. It is the customer's responsibility to ensure that the product is suitable for the intended use and to accept any liability arising from its use.

Transportation & storage

Individual pallets must be transported. Transport must only be carried out with covered vehicles.

The panel packages must be stored in well-ventilated, indoor, and dry rooms, protected from atmospheric agents and sunlight. The panels must be stored with their own pallet, which must lie on a flat, dry surface. For prolonged storage, at least a part of the protective plastic should be removed from the packages. The panels must never come into direct contact with the ground. Do not stack more than two pallets.

Technical data

| * wet over dry | Unit of measure | Value |

| STANDARD DIMENSIONS** AND GEOMETRY | ||

|

Length |

mm | 2500 3000 3050 |

| Width | mm | 1200 1250 |

| Thickness | 5-6-8-10-12 | |

|

Tolerances on nominal dimensions |

Classification according to EN 12467:2018 |

Level 1 |

| - on length | mm | ± 2 |

| - on width | mm | ± 1 |

| - on straightness of edges | % | 0,1 |

| - on squareness of edges | mm/m | 2 |

| - on thickness for smooth sheets | mm | ± 0,2 |

|

Nominal weight |

kg/m2 | 14,4 (t=8mm)

18,0 (t=10mm) 21,6 (t=12mm) |

| PHYSICAL PROPERTIES | ||

| Density (dry) | kg/m³ | 1600 ± 50 |

| MECHANICAL PROPERTIES | ||

| E modulus of elasticity (dry) | ||

| - longitudinal | GPa | 14 |

| - transversal | GPa | 12 |

| E modulus of elasticity (wet) | ||

| - longitudinal | GPa | 11 |

| - transversal | GPa | 9 |

| Bending strength (wet) | MPa | ≥24 |

| Resistance (Charpy test) | According to EN 179-1:2010 | |

| - longitudinal | kJ/m2 | 4,3 |

| - transversal | kJ/m2 | 3,1 |

| HYGROMETRICAL PROPERTIES | ||

| Natural humidity | % | 10 ÷ 15 |

| Max water absorption* | % | ≤25 |

| Moisture movement – Relative humidity change from 30% to 90% | ||

| - longitudinal | mm/m | 0,7 |

| - transversal | mm/m | 0,8 |

| THERMAL AND WATER VAPOUR PROPERTIES (untreated boards) | ||

| Vapor resistance factor, μ – according to EN 12572:2016 | --- | 49 |

| Thermal conductivity – according to EN 12664:2002 | W/mK | 0,42 |

| Thermal expansion coefficient – according to EN 10545-8:2014 | ||

| - longitudinal | 1/°C | 1,71•10-6 |

| - transversal | 1/°C | 0,58•10-6 |

| OTHER PROPERTIES | ||

| Superior calorific power (through coloured) | MJ/kg | 1,2 (12 mm)

1,3 (5 mm) |

| Fire rating class | According to EN 13501-1 | A2 s1 d0 |

| Freeze-thaw performance | RL ≥ 0,75 | |

| Durability classification | According to EN 12467:2018 | category A |

| Strength classification | According to EN 12467:2018 |

class 5 |

| CE marked product according to | --------- | EN12467 |