Aquafire

Aquafire are cement composite panels – light, non-flammable (class A1), with high thermal insulation performance. The panels are very easy to cut, waterproof, and can be used both indoors and outdoors. Aquafire panels have a curvature radius of 2m, making them perfect for use in curved buildings and interior walls. Aquafire panels do not deform, do not crumble and are an excellent material for the application of ceramic tiles, glass mosaics, brickwork, or other types of coating. Can be used in seamless systems of ventilated facades.

Product sizes

Size: 1200 x 2000 mm

Thickness: 12.5 mm

Properties

- Extremely light-weight.

- With high insulation values.

- Very resistant to water, also against chemical and biological effects.

- Can be used for interior or exterior work.

- Do not split, deform, crack or crumble.

Application

Suitable for use both indoors and outdoors:

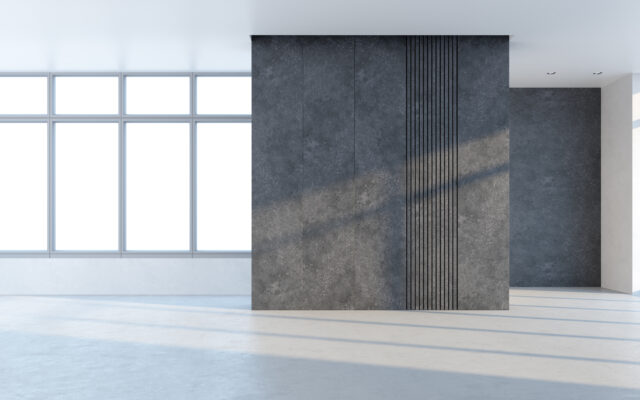

- Ventilated facades, external cladding of buildings, external walls and non-bearing structures.

- Curved surfaces.

- Floors, roofs and canopies, balconies and terraces , attics, wine cellars and technical rooms.

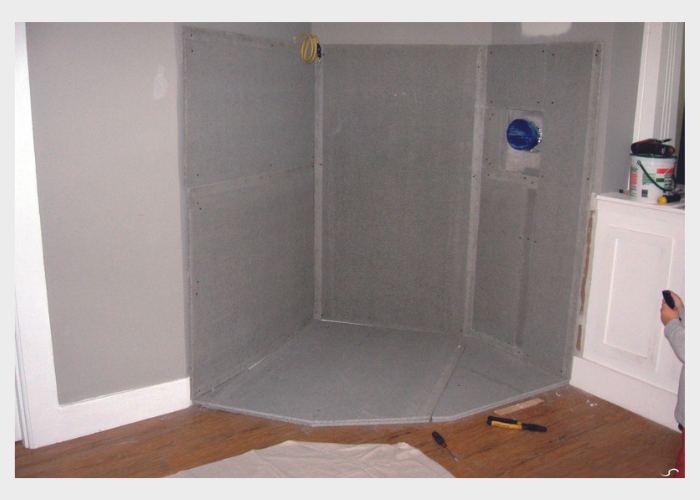

- Ideal for rooms with a high level of humidity - showers, bathrooms, swimming pools, spa areas, saunas, saunas, dry cleaners and kitchens.

- As a coating in structures exposed to high temperatures, such as chimneys and boiler rooms.

- In certified fireproof solutions (up to 240 min) - walls, partitions, overhangs, ceilings.

Installation

Outdoor

- The boards should be installed on suitable metallic frames depending on whether the installation is on walls, linings walls, ceiling, or ventilated façade.

- We recommend using metallic profiles in compliance with the UNI EN standard of 10/10 mm thickness. The galvanization must be greater than or equal to 200 gr/m2.

- Arrange the frames one step no greater than 40 cm.

- Aquafire boards must be installed perpendicular to the metallic frame with the cut side exposed. The joints must be staggered as in any normal dry covering application.

- Between one board and the next leave about 3-4 mm.

- Keep the sheets off the ground 12 / 12.5 mm with the help of a scrap of sheet (which should then be removed) to prevent the possible lift of capillary moisture, salts, or impurities of the support bases, and to allow the normal expansion of the materials.

- Fixing Aquafire boards with Screws Aquafire Star screwing from cut side with step 20 cm (15 cm for horizontal applications); a distance of about 15 mm is indicated from the edge to best take advantage of the boards contact with the large surface of the screw head.

- Install an expansion joint every 12 linear meters, both in horizontal and vertical direction;

- Where is expected a glued surface coating, at this point the wall is ready to host it.

- If instead is expected a traditional finishing, spread a layer of Rasante Aquafire on the entire surface of the boards with a notched trowel steel, making sure to penetrate the coating inside the joints between boards.

- Embed the Rete Aquafire mesh in the cement coat which has just been spread, taking care to hide it completely, working with the smooth side of the trowel steel. Mesh joints will be overlapped by 100mm, following the premarked line.

- At this point the final thickness of coating must be 3mm.

- Complete the surface with a finish plaster walls like acrylic plaster, acrylic-siloxane or siloxane.

Indoor

- The boards will be installed on suitable metallic frames depending on whether the installation is on walls, linings walls or ceiling.

- We recommend using metallic profiles in compliance with the UNI EN standard with 6/10mm thickness.

- Arrange the frames one step no greater than 60cm.

- Aquafire boards must be installed to the metallic frame with the cut side exposed. The joints must be staggered as in any normal dry covering application.

- Between one board and the next leave about 3-4 mm.

- Keep the sheets off the ground 12 / 12.5mm with the help of a scrap of sheet (which should then be removed) to prevent the possible lift of capillary moisture, salts or impurities of the support bases, and to allow the normal expansion of the materials.

- Fixing Aquafire boards with Screws Aquafire Star screwing from cut side with step 25cm (15cm for horizontal applications); a distance of about 15 mm is indicated from the edge in order to best take advantage of the boards contact with the large surface of the screw head.

- Install an expansion joint every 12 linear meter, both in horizontal and vertical direction;

- Where is expected a glued surface coating, at this point the wall is ready to host it.

- If instead is expected a traditional finishing, spread a layer of Finish on the entire surface of the boards with a notched trowel steel, making sure to penetrate the coating inside the joints between boards.

- Smoothing the surface embedding the Rete Aquafire mesh in the coating which has just been spread, taking care to hide it completely, working with the smooth side of the trowel steel. Mesh joints will be overlapped by 100mm, following the premarked line.

- Now the wall is ready for painting.

Curved surface

To create curved surfaces, you can use the whole Aquafire boards up to a minimum radius of 2 meters. For rays less and up to 90 cm use boards of a width of 30cm, screwing them with Screws Aquafire Star to step 10 cm.

Documentation

Technical data

| Value | Tolerance | |

| Length | 2 000 mm | ±5 |

| Width | 1 200 mm | ±3,6 |

| Thickness | 12,5 mm | ±1,2 |

| Density | 960 kg/m³ | ±15% |

| Weight | 12 kg/m² | ±15% |

| Reaction to fire | Non-flammable - A1 class |