Building panels that make construction works faster, more productive and meet the ever-increasing quality and safety requirements for construction materials. We offer ultra-lightweight, fire and water-resistant building panels from Italy.

Endless possibilities for use

Aquafire panels are industrially reinforced for increased mechanical resistance, which opens up a wide range of applications in construction work. They are suitable for use in both interior and exterior constructions – grey finishes, seamless systems for ventilated facades, curved surfaces, floors, walls, wet rooms, swimming pools, ships, etc. Due to their high mechanical properties and moisture resistance, this material is particularly popular for installation in areas where the attachment of various shelves, kitchen cabinets, televisions and other furniture or structures is planned, and it has a particularly low coefficient of linear expansion which reduces cracking in facades and other seamless system embedment areas.

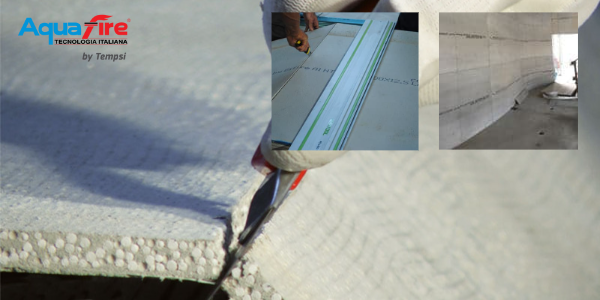

Assembly technique

The panels are bolted to galvanized steel or timber frames to form a seamless system in the facades. Decorative plasters, tiles and other finishing materials are applied directly to the panel on top of a pre-formed reinforcement layer. In the interior, like plasterboard, it is mounted on profiles. The panels are easy to cut, punch and drill. No specialized power tools are required.

When working with Aquafire panels, use screws with socket heads specifically designed for the product. The manufacturer’s bolt layout – bolt spacing and edge distances – must be followed. Otherwise, uneven load distribution on the panel can occur, leading to buckling, cracking and even tearing of the panels. As a structural material, Aquafire in a single layer is also stronger than plasterboard.

Material properties

The panels are highly resistant to chemical and biological attack. High mechanical and moisture resistance make them particularly suitable for rooms with high humidity. The product is certified for marine use. Aquafire panels have a particularly low coefficient of linear expansion, which reduces the risk of facade cracking.

Unquestionable benefits

Class A1 reaction to fire, i.e. completely non-combustible. The manufacturer offers various passive fire resistance solutions that allow the construction of walls with EI60 fire resistance requirements, withstanding 240 minutes of burning time. CLT(cross laminated timber) materials are becoming increasingly popular in Latvia and Aquafire is a certified solution for this type of timber construction. The manufacturer offers a solution where the panel is screwed in a single layer on top of the glued timber, resulting in a fire-resistant construction. The structure is physically built and subjected to combustion in a laboratory, as confirmed by test report certificates. This solution is increasingly required by the SFRS when commissioning buildings.

High resistance to mechanical impact

Aquafire is Impact Resist certified, which means it is shock resistant. For example, when installed in the walls of public spaces, the panels offer significantly greater resistance to mechanical damage (punctures, scratches, dents, etc.). The A+ emission class is the highest possible for indoor finishes, which means low emissions and is a testament to air friendliness. The mechanical resistance of the sheets is maintained even in the presence of moisture.

The manufacturer provides a 10-year warranty, provided that the conditions for transport, storage and installation are met.