Aquafire

Aquafire ir cementa kompozītu paneļi – viegli, nedegoši (A1 klase), ar augstiem siltumizolācijas rādītājiem. Paneļi ir ļoti viegli sagriežami, ūdensizturīgi, un tos iespējams izmantot gan iekšdarbos, gan ārdarbos. Aquafire paneļiem ir izliekuma rādiuss 2m, tāpēc ir lieliski piemēroti izmantošanai izliektās ēkās un iekšējās sienās. Aquafire paneļi nedeformējas, nedrūp un ir izcils materiāls keramisko flīžu, stikla mozaīkas, ķieģeļu seguma vai cita veida pārklājuma uzklāšanai. Izmantojami ventilējamo fasāžu bezšuvju sistēmās.

Produkta izmēri

Izmērs: 1200 x 2000 mm

Biezums: 12.5 mm

Īpašības

- Īpaši vieglas.

- Ar augstu izolācijas vērtību.

- Ļoti izturīgas pret ūdeni, arī pret ķīmisko un bioloģisko iedarbību.

- Var izmantot iekšdarbiem vai ārdarbiem.

- Nesadalās, nedeformējas, neplaisā un nedrūp.

Pielietojums

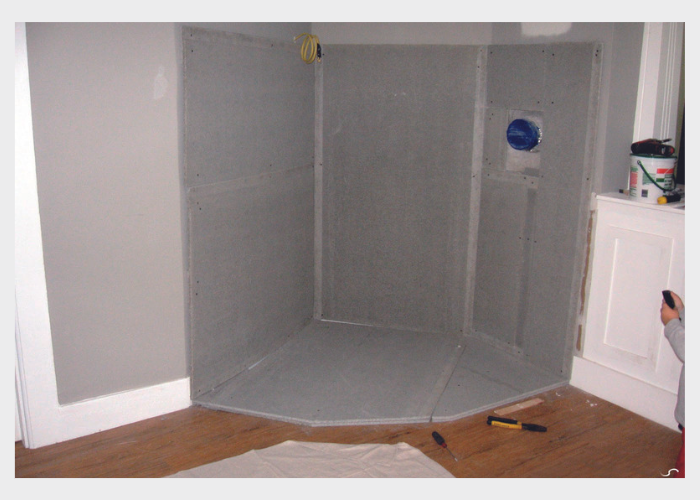

Aquafire paneļi ir ļoti izturīgi, arī pret ķīmisko un bioloģisko iedarbību, padarot tos piemērotus izmantošanai gan iekštelpās, gan ārpus tām, ieskaitot ēku ārējo apšuvumu, ventilējamās fasādēs, ārējās sienās, nenesošajās konstrukcijās, izliektās virsmās, grīdās, jumtos un nojumēs, balkonos un terasēs, mansardos, vīna pagrabos un tehniskajās telpās. Aquafire ir ideāli piemērots telpām, kurās ir augsts mitruma līmenis – dušas, vannas istabas, peldbaseini, spa zonas, saunas, pirtis, ķīmiskās tīrītavas un virtuvēs. Kā pārklājumu konstrukcijās, kas pakļautas augstai temperatūrai, piemēram, skursteņos un katlu telpās.

Kā arī sertificētos ugunsdrošos risinājumos (līdz 240 min) - sienas, starpsienas, pārkares, griesti.

Montāža

Outdoor

- The boards should be installed on suitable metallic frames depending on whether the installation is on walls, linings walls, ceiling, or ventilated façade.

- We recommend using metallic profiles in compliance with the UNI EN standard of 10/10 mm thickness. The galvanization must be greater than or equal to 200 gr/m2.

- Arrange the frames one step no greater than 40 cm.

- Aquafire boards must be installed perpendicular to the metallic frame with the cut side exposed. The joints must be staggered as in any normal dry covering application.

- Between one board and the next leave about 3-4 mm.

- Keep the sheets off the ground 12 / 12.5 mm with the help of a scrap of sheet (which should then be removed) to prevent the possible lift of capillary moisture, salts, or impurities of the support bases, and to allow the normal expansion of the materials.

- Fixing Aquafire boards with Screws Aquafire Star screwing from cut side with step 20 cm (15 cm for horizontal applications); a distance of about 15 mm is indicated from the edge to best take advantage of the boards contact with the large surface of the screw head.

- Install an expansion joint every 12 linear meters, both in horizontal and vertical direction;

- Where is expected a glued surface coating, at this point the wall is ready to host it.

- If instead is expected a traditional finishing, spread a layer of Rasante Aquafire on the entire surface of the boards with a notched trowel steel, making sure to penetrate the coating inside the joints between boards.

- Embed the Rete Aquafire mesh in the cement coat which has just been spread, taking care to hide it completely, working with the smooth side of the trowel steel. Mesh joints will be overlapped by 100mm, following the premarked line.

- At this point the final thickness of coating must be 3mm.

- Complete the surface with a finish plaster walls like acrylic plaster, acrylic-siloxane or siloxane.

Indoor

- The boards will be installed on suitable metallic frames depending on whether the installation is on walls, linings walls or ceiling.

- We recommend using metallic profiles in compliance with the UNI EN standard with 6/10mm thickness.

- Arrange the frames one step no greater than 60cm.

- Aquafire boards must be installed to the metallic frame with the cut side exposed. The joints must be staggered as in any normal dry covering application.

- Between one board and the next leave about 3-4 mm.

- Keep the sheets off the ground 12 / 12.5mm with the help of a scrap of sheet (which should then be removed) to prevent the possible lift of capillary moisture, salts or impurities of the support bases, and to allow the normal expansion of the materials.

- Fixing Aquafire boards with Screws Aquafire Star screwing from cut side with step 25cm (15cm for horizontal applications); a distance of about 15 mm is indicated from the edge in order to best take advantage of the boards contact with the large surface of the screw head.

- Install an expansion joint every 12 linear meter, both in horizontal and vertical direction;

- Where is expected a glued surface coating, at this point the wall is ready to host it.

- If instead is expected a traditional finishing, spread a layer of Finish on the entire surface of the boards with a notched trowel steel, making sure to penetrate the coating inside the joints between boards.

- Smoothing the surface embedding the Rete Aquafire mesh in the coating which has just been spread, taking care to hide it completely, working with the smooth side of the trowel steel. Mesh joints will be overlapped by 100mm, following the premarked line.

- Now the wall is ready for painting.

Curved surface

To create curved surfaces, you can use the whole Aquafire boards up to a minimum radius of 2 meters. For rays less and up to 90 cm use boards of a width of 30cm, screwing them with Screws Aquafire Star to step 10 cm.

Tehniskie dati

| Vērtība | Tolerance | |

| Garums | 2 000 mm | ±5 |

| Platums | 1 200 mm | ±3,6 |

| Biezums | 12,5 mm | ±1,2 |

| Blīvums | 960 kg/m³ | ±15% |

| Svars | 12 kg/m² | ±15% |

| Ugunsizturība | Nedegošas - A1 |